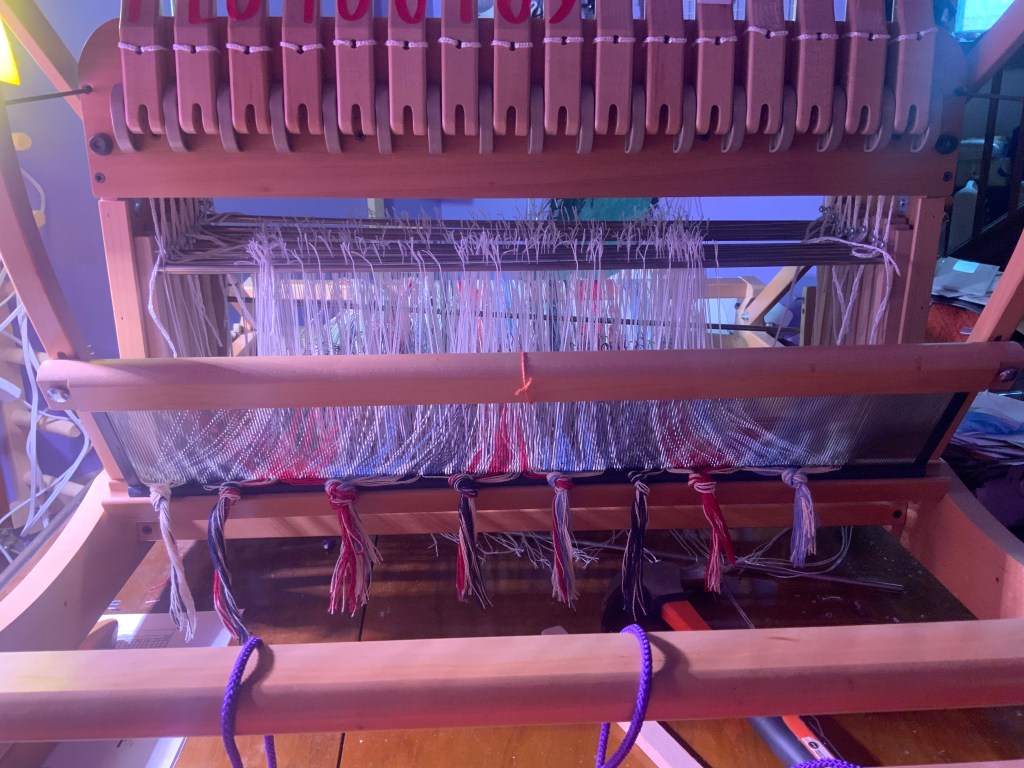

I now have my 16 shaft table loom warped up completely and I have been weaving on it this week. A couple of threads snapped and a couple are floating rather than separating so I have to figure out what is going on with them. After I finished weaving the first towel, I decided to take each shaft off of its rail and take off the extra heddles that I had on the end. This was going very well until I reached shaft 14 and then the shaft decided to snap on me, essentially the bottom came off before the top was out of the rail, and it snapped. I was able to glue it back together using gorilla glue, however, that happened just this morning so I will not be able to put it back on until tomorrow morning.

I know that the gorilla wood glue worked because after half an hour the shaft stayed together without the clamp on. I did manage to get all of the extra heddle off and shifted where the last shaft is going to be by adding the pieces onto the other heddle. Essentially now only the 16th shaft is missing the part that keeps the heddle rods in place. Do I regret doing all of this, while the loom is completely warped up, not really. Considering how much time and effort it takes to warp up the loom, loosening the warp from the back beam and allowing the heddles to shift in place seems to be the best way to do this. That being said, I have not found out where the sticky warps are nor whether anything is shifted or twisted, so wait and see if this actually works or not. Since I am having a Weaving Guild meeting on Saturday and they asked us to bring our own place setting, I’m going to wash the towel now that I’ve hemmed it and see how it works.

There is one more aspect to this saga and that is the paper that I used to wind the back warp. Since it was not exactly the same size as the back warp beam, it wound up crinkling and wrinkling. Those crinkles and wrinkles cause the warped be held at a different tension which completely messed up my front tension. I should’ve seen this coming however, I did not. I am still debating different ways to potentially resolve this issue. The back warp reel is actually quite wide, though it isn’t 36 inches wide which is what I think the paper is.

I believe taking off the extra heddles will give me room to figure out which of my warps are crossing or doing other things that cause me to not get a clean shed. I also believe that if I can find some way to wind the warp on with even tension I will solve my loose warp problem, though I do not look forward to unrolling the entire warp just to try to roll it back on the back beam with even tension. Perhaps unrolling the back beam and pulling it through the front reed and heddles will help me figure out my threading problems, then I can concentrate on the tension problems. I hope to get both of those problems solved this week, though again it will all have to wait until tomorrow morning when I can get the last shaft fixed.

As you can probably tell, this has been my all consuming project this past week. The quilt as you go project went well, not everyone finished since I had between 16-18 (I lost count) people wanting to do the project. As a result, even though Wednesday-Sunday I’m supposed to be off, I will be coming in to work for 2 hours to set up and help everyone finish their potholders. Each person will be making 1 and I have enough supplies for 12. I’m also teaching Scissor Fobs on Saturday, so I will really have Wednesday, Friday, and Sunday off. That is alright, I will use the ‘on days’ to run other errands and take care of other chores around the house.

I think that is it for this week, so until next time remember to Live Life a Little More Abstract!